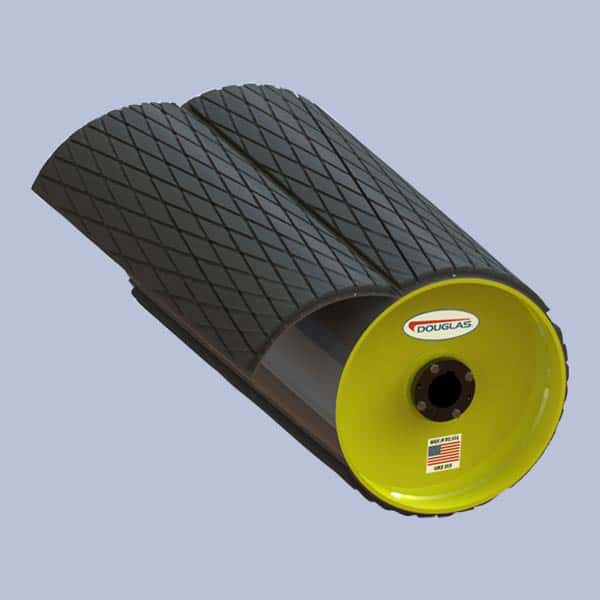

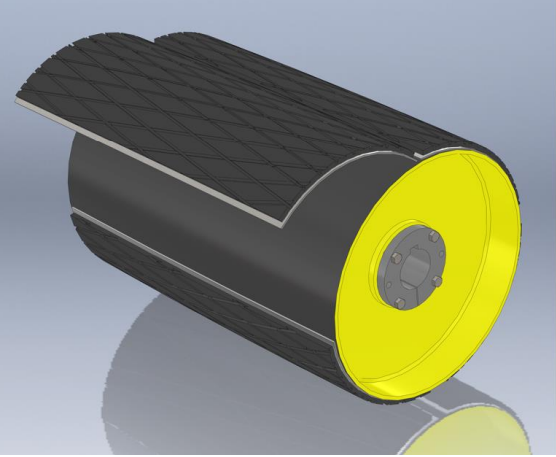

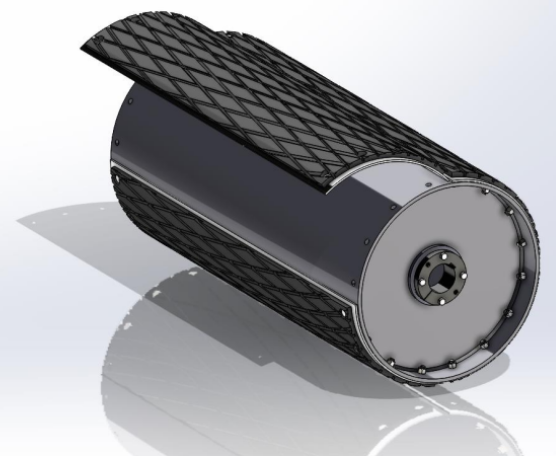

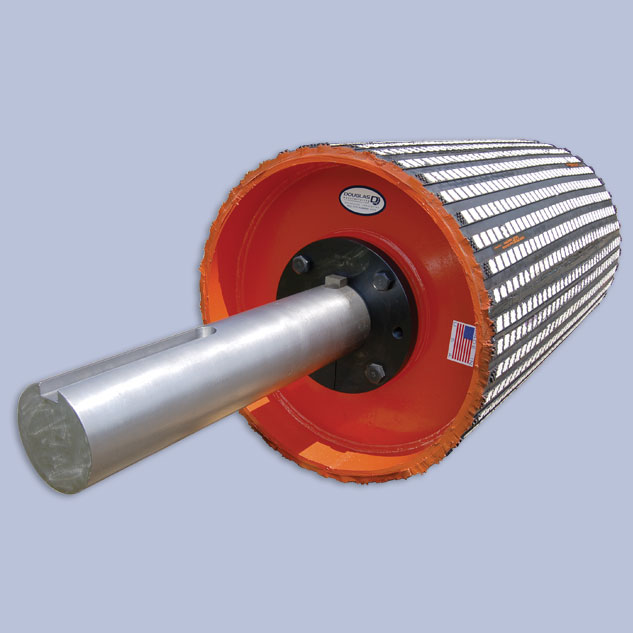

Douglas Manufacturing Replaceable Rim Lagging® is an innovative way to cover new pulleys and recover old pulleys.

Engineered sections are made for specific pulleys and effectively cover the pulley face in a protective shell of rubber and steel and are an ideal way to save money and time.

Design Features

- Up to 70% labor savings on installation

- 30% more coverage resulting in increased traction

- 3/16” solid steel backing plate

- 1/2” 60-65 Durometer SBR compound suitable for various applications

- The ability to re-lag the pulley in the field without removing it from the conveyor

- Roll Crown Face standard

- Diamond grooving is standard, making installation fast and easy

- Fewer sections mean fewer gaps and more rubber coverage

- No excess or wasted material — No undesirable seams

- Bolt-on option available

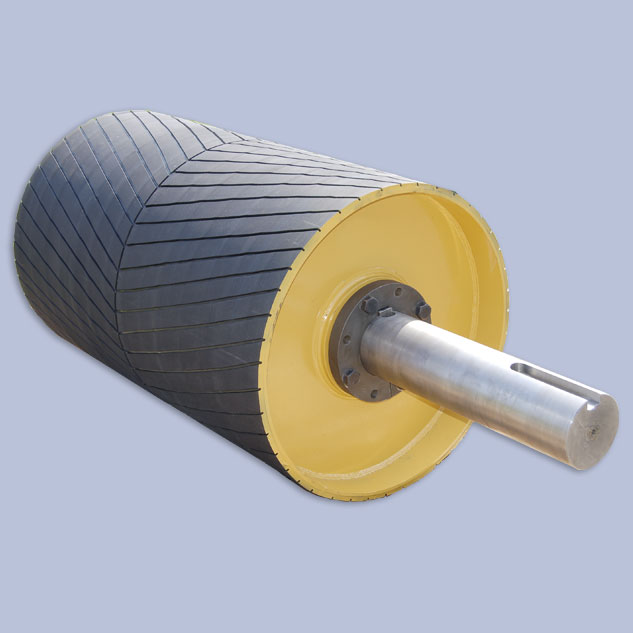

RRL – Weld-on Replaceable Rim Lagging

RRB – Bolt-on Replaceable Rim Lagging

Vulcanized Pulley Lagging

The Replaceable Rim Lagging Advantage

The conveyor systems that keep your business running work hard and might be exposed to harsh open elements. Eventually, wear and tear will reduce your conveyor’s efficiency and result in costly downtime.

Replaceable Rim Lagging offers a solution to this problem. It can help present costly downtime, extend pulley life by shielding the rim from excessive wear and even boost productivity by maximizing traction.

Douglas Manufacturing can offer a productivity boost and long-term protection with its top-of-the-line options. Replaceable Rim Lagging is designed to fit existing pulleys, saving you time and money.

Douglas Manufacturing – Replaceable Rim Lagging

Replaceable rim lagging offers the advantage of the simple and effective application to new and older pulleys. Replaceable Rim Lagging can even be applied to pulleys without removing them from the conveyor, making it a convenient and cost-effective option.

We offer a unique ability to re-lag a pulley in the field without removing it from the conveyor. This can result in up to 70% labor savings on installation.

The ability to re-lag a pulley plays a vital role in the efficient operation of conveyor systems. Well-made and properly applied replaceable rim lagging:

- extends the life of the conveyor pulley

- shields the conveyor pulley from abrasion

- increases traction to help eliminate slippage and improve performance

Contact Douglas Manufacturing

If you are interested in learning more about replaceable rim lagging or other products that Douglas Manufacturing offers, contact us or call 800-884-0064.

All of our products are made in our Pell City, Alabama plant. We are also proud to provide emergency services resulting in lead times of as little as 24 hours for critical situations.