There are many different types of pulleys and lagging systems available today. Each of them is slightly different and offers different uses. If you are in the market you need to make sure to do your research and know what is right for you. Here are a few facts about pulleys and lagging that you may not have previously known.

Finding The Right Pulley

Finding the right pulley can be a challenge if you do not know what you are looking at so it is best to turn to a professional for help. There can be many pulleys that do the job but only one that is going to do the absolute best for your application so you need to be sure you find that one.

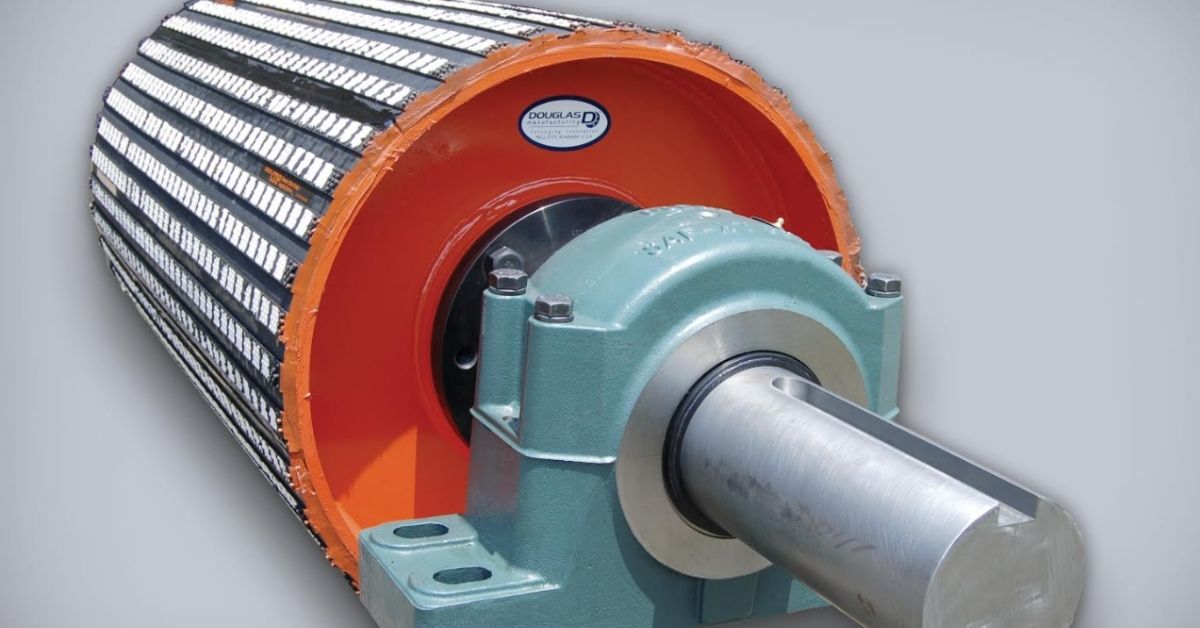

Drum pulleys and wing pulleys are two of the more popular types of pulleys because of their durability, and years in the business. There are different pulley classes and selecting the correct shaft size is critical to having a pulley achieve its full-service life. In that same light, it is important to understand the effect of bearing centers on your pulleys and take into account the effect of overhung loads on your drive pulleys.

There are several different designs of drum pulleys available and selecting the right pulley for your application can help ensure years of efficient, trouble-free operation. There are several options with wing pulleys including new generation self-cleaning pulleys that are more efficient, quieter, and smoother running than traditional wing pulleys.

Types of Lagging

Lagging is primarily applied to pulleys to improve traction, but it may also be applied to improve wear life and provide a higher level of self-cleaning ability. There are different types of lagging but the two most popular are ceramic lagging and rubber lagging.

Ceramic Lagging

Ceramic lagging is used to help eliminate belt slippage in messy environments and is also employed where high wear (abrasion) is a concern. In fact, high-quality ceramic lagging can increase traction so that belt slippage is no longer a problem, and it can help improve the efficiency of your conveyor by allowing you to reduce belt tension. Reduced belt tension means that your belt and the mechanical components on your conveyor system will last longer.

There are many different variations available of ceramic that can be smooth or rough depending on the requirement of your application. When considering the option of ceramic laggings remember to keep your goals in mind, and select the right style of lagging to achieve those goals.

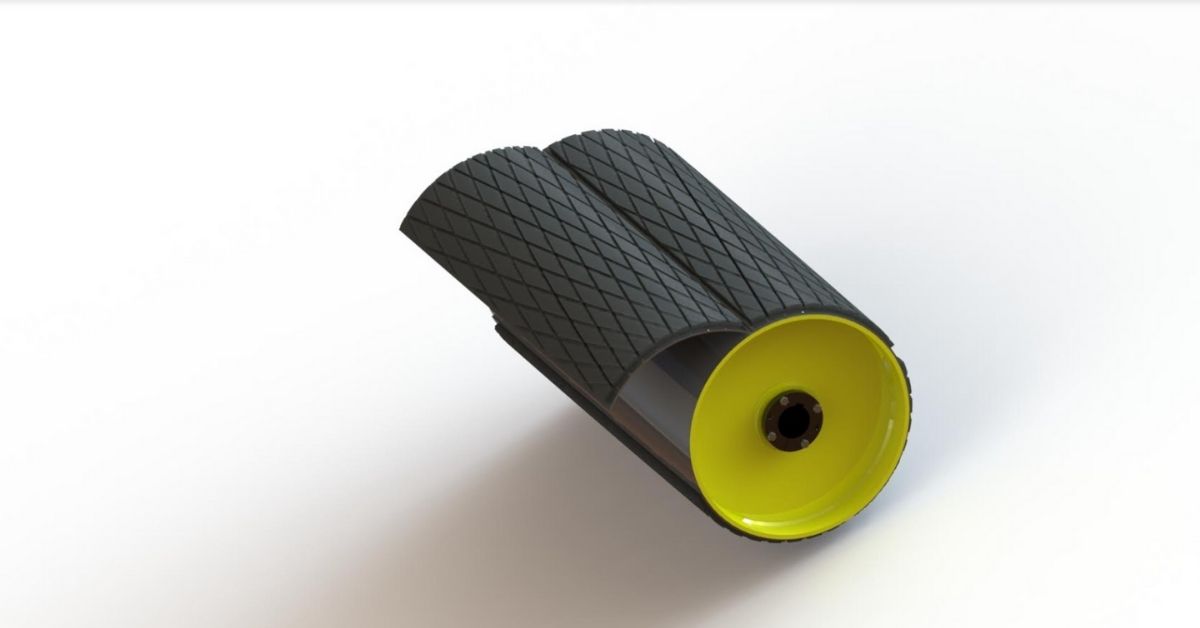

Rubber Lagging

Rubber lagging is used in less abrasive conditions but will reduce belt slippage in wet conditions. Rubber lagging can also be customized by thickness, groove style, and the hardness of the rubber referred to as the “durometer” can be specified to help improve overall performance.

Lagged pulleys are most commonly found on the head pulley, the drive pulley, and lagging should be applied to pulleys that contact the carrying side of the belt such as snub, and bend pulleys.

Replaceable Lagging

Replaceable Rim lagging is also offered so that you can continue using the product after years of service. Your pulley may be in good condition other than lagging wear. Now it is possible to change out lagging in the field. Replaceable rim lagging will allow your product to continue being as efficient as it was the day you bought it. There are weld-on or bolt-on options. The best choice depends on accessibility when it is time to service the pulley.

Douglas Can Help

No matter what you are looking for, the professionals at Douglas Manufacturing will be able to help you. With years of experience and a friendly team of experts, Douglas would be happy to walk you through any questions that you may come across.

Recent Comments