Permanent Magnetics

Douglas Permanent Magnetic Separators and Pulleys are manufactured in the United States using only the highest quality materials so that our customers can protect their equipment and purify their material.

Ready for any job, Douglas permanent magnetic separators are available in both heavy duty and super duty field strengths, as well as manual and self-cleaning configurations. All of which are shipped complete and ready for installation to make life just a little bit easier for you.

PMG – CEMA Class Permanent Magnetic Pulley

HMG – Standard Manual Cleaning Permanent Magnetic Separator

CBM – Standard Self Cleaning Permanent Magnetic Separator

XMG – Super Power Manual Cleaning Permanent Magnetic Separator

CBX – Super Power Self Cleaning Permanent Magnetic Separator

CBO – SELF CLEANING PERMANENT MAGNETIC SEPARATOR FOR PORTABLE EQUIPMENT

Permanent Magnet for Conveyor Belt: Magnetic Separators and Pulleys

Made in the USA, Douglas Permanent Magnets provide the assurance you need to know that you’re protecting your product and expensive equipment downstream from the conveyor.

Permanent separators help separate tramp ferrous metals from conveyed material. They are typically suspended above the belt, which allows them to effectively and efficiently pull metal up and away from the product flow before discharging it safely away from the conveyor. This means our customers can continually provide a quality end product without the interference of ferrous metals.

Ready for any job, Douglas permanent magnets are available in both heavy duty and super duty field strengths, as well as manual and self-cleaning configurations. All of which are shipped complete and ready for installation to make life just a little bit easier for you.

At Douglas Manufacturing, we offer five types of permanent magnets options for the conveyor belt:

PMG – CEMA Class Permanent Magnetic Pulley

HMG – Standard Manual Cleaning Permanent Magnetic Separator

CBM – Standard Self Cleaning Permanent Magnetic Separator

XMG – Super Power Manual Cleaning Permanent Magnetic Separator

CBX – Super Power Self Cleaning Permanent Magnetic Separator

PMG – CEMA Class Permanent Magnetic Pulley

Douglas magnetic pulleys are manufactured to meet or exceed CEMA/ANSI standards and can be used for just about any head pulley application. With our magnetic pulleys, you’ll be able to remove potentially harmful tramp ferrous metal before it damages expensive processing equipment.

Our CEMA Class Permanent Magnetic Head Pulleys (PMG) also offer Exclusive One Piece Rolled in Crown to ensure consistent, proper belt tracking and tighter tolerances. The PMG also offers hubs and bushings that are interchangeable with XT® style, and Standard Stainless Steel Rims and crown face pulleys. Flat face must be specified.

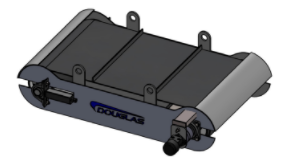

CBM – Standard Self Cleaning Permanent Magnetic Separator + CBX – Super Power Self Cleaning Permanent Magnetic Separator

Our CBM and CBX Self Cleaning Permanent Magnetic Separators are made in the USA of heavy grade steel. They are complete with CEMA-class lagged crown face head pulley, tail pulley and Slide Tube® belt take-ups. They feature a heavy duty rubber cover belt standard with hot vulcanized cleats. Self cleaning pulleys save both time and money, as no man hours are needed for maintenance. The magnetic separators are CLASS II shaft mount gear drive with TEFC motor.

HMG – Standard Manual Cleaning Permanent Magnetic Separator + XMG – Super Power Manual Cleaning Permanent Magnetic Separators

Our HMG and XMG Standard and Super Power Manual Cleaning Permanent Magnetic

Separators have a pivot arm or cleaning drawer available for easy cleaning. No power requirements are necessary, making them easy to install anywhere. Manual cleaning for ferrous metal is required.

Not sure which configuration is right for you? No problem. Contact us today to discuss your needs with one of our engineers.

About Douglas Manufacturing

Established in 1978, Douglas is a leading manufacturer of conveyor components and engineered conveying solutions based in Pell City, Alabama. The Douglas engineering department uses the latest technology available to select and design some of the best components and engineered conveying solutions in the industry. Using this technology Douglas can design and select components for new applications, design custom solutions for new applications and offer problem solving assistance with existing applications. This technology and the experience of Douglas’ engineering staff result in the most economical solutions and the fastest solution cycle times available in the industry.

Douglas conveyor components are proudly manufactured in the United States of America. From stock pulleys and idlers to custom engineered conveying solutions the people of Douglas are dedicated to Conveying Innovation™ every day.

Douglas manufactures more than forty different high quality conveyor components including: CEMA Class/Heavy Duty Drum & Wing Pulleys, Mine Duty Drum and Wing Pulleys, Quarry Duty Drum and Wing Pulleys, Extreme Duty Drum & Wing Pulleys, Engineered Class Pulleys, Pulley Lagging, Shafting, a complete line of CEMA B, C or D Idlers, Take-Ups, Impact Beds and Permanent Magnetic Conveyor Pulleys, Self-Cleaning & Manual Cleaning Magnetic Separators and innovative conveyor accessories including the patented Guardian3™ Premium Return Roll Guard.

![pulleys_wing_lg[1]](https://www.douglasmanufacturing.com/img/magnetics/magnetics_PMG.jpg)

![pulleys_wing_lg[1]](https://www.douglasmanufacturing.com/img/magnetics/magnetics_HMG.jpg)

![pulleys_wing_lg[1]](https://www.douglasmanufacturing.com/img/magnetics/magnetics_CBM.jpg)

![pulleys_wing_lg[1]](https://www.douglasmanufacturing.com/img/magnetics/magnetics_XMG.jpg)

![pulleys_wing_lg[1]](https://www.douglasmanufacturing.com/img/magnetics/magnetics_CBX.jpg)